Applications

Automotive

Calibration maintains reliability in engine performance, emissions testing, and safety systems like airbags and braking, ensuring vehicle safety and efficiency.

Engineering & Power Sector

Guarantees accuracy in design and manufacturing tools, CNC machines, and measurement instruments, supporting innovation and quality in engineering projects and in power sector for precise weight measurement and safety monitoring.

Steel

Ensures precision in thickness gauges, hardness testers, and temperature controls, which are essential for meeting industry standards and specifications.

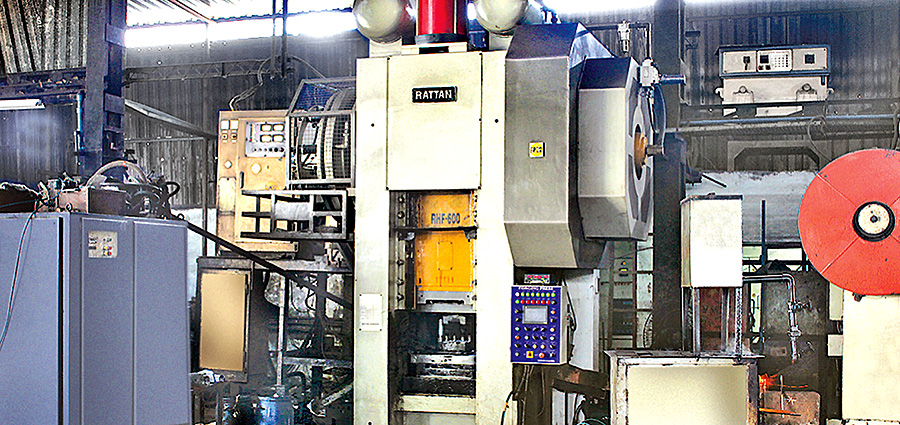

Forging

Ensures consistency in press force, die alignment, and material properties, which are vital for producing high-quality forged components.

Defence

Calibration ensures precision in weapon systems, targeting accuracy, and navigation instruments, critical for mission success and safety.

Construction

Verifying the accuracy of surveying tools, heavy machinery, and material testing equipment is crucial for structural integrity and project success.

Rubber

Calibration maintains quality in tensile strength, elasticity measurements, and curing processes, ensuring product durability and performance.

Pharma

Accurate calibration of dosage measurements, lab equipment, and environmental controls is essential for maintaining drug efficacy and compliance with regulatory standards.